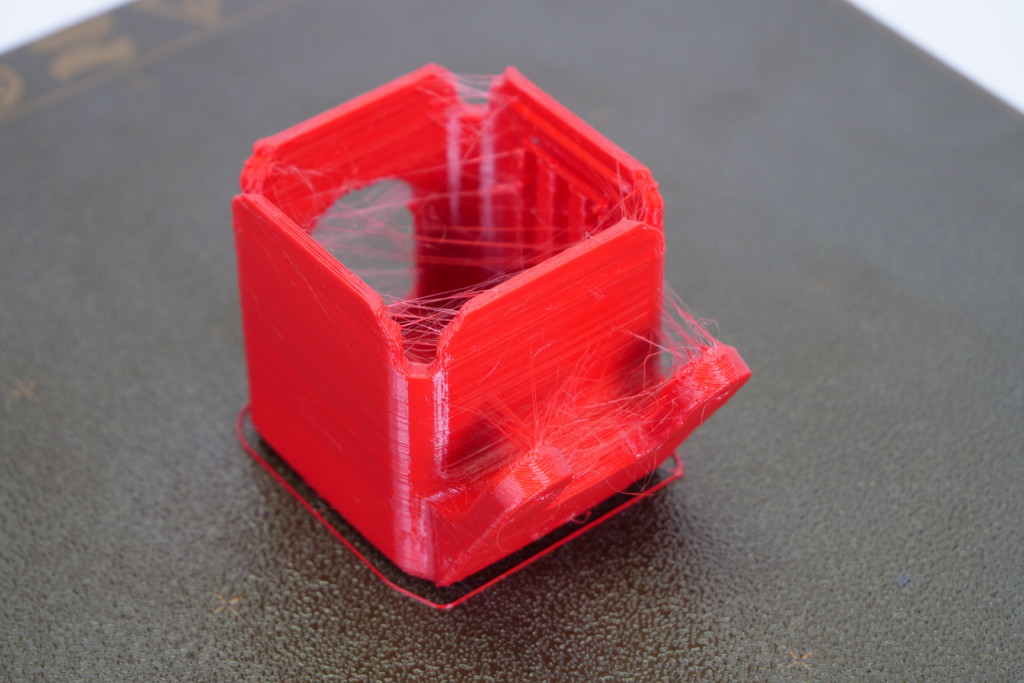

3d printer stringing test

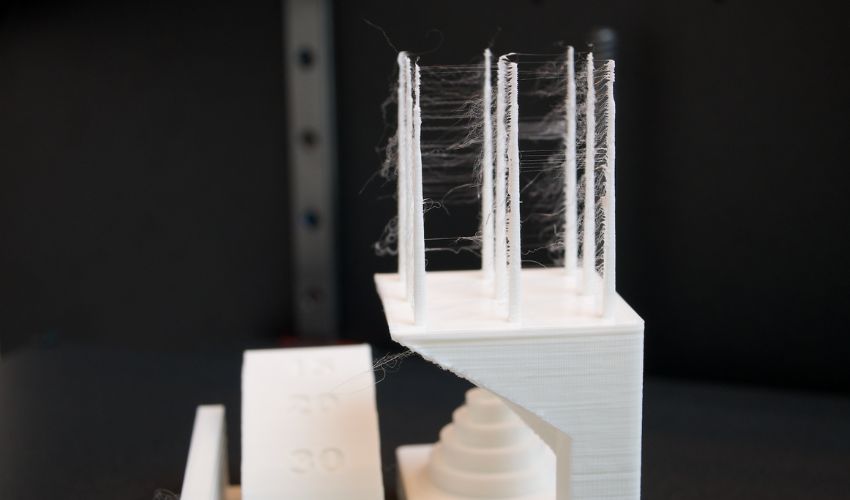

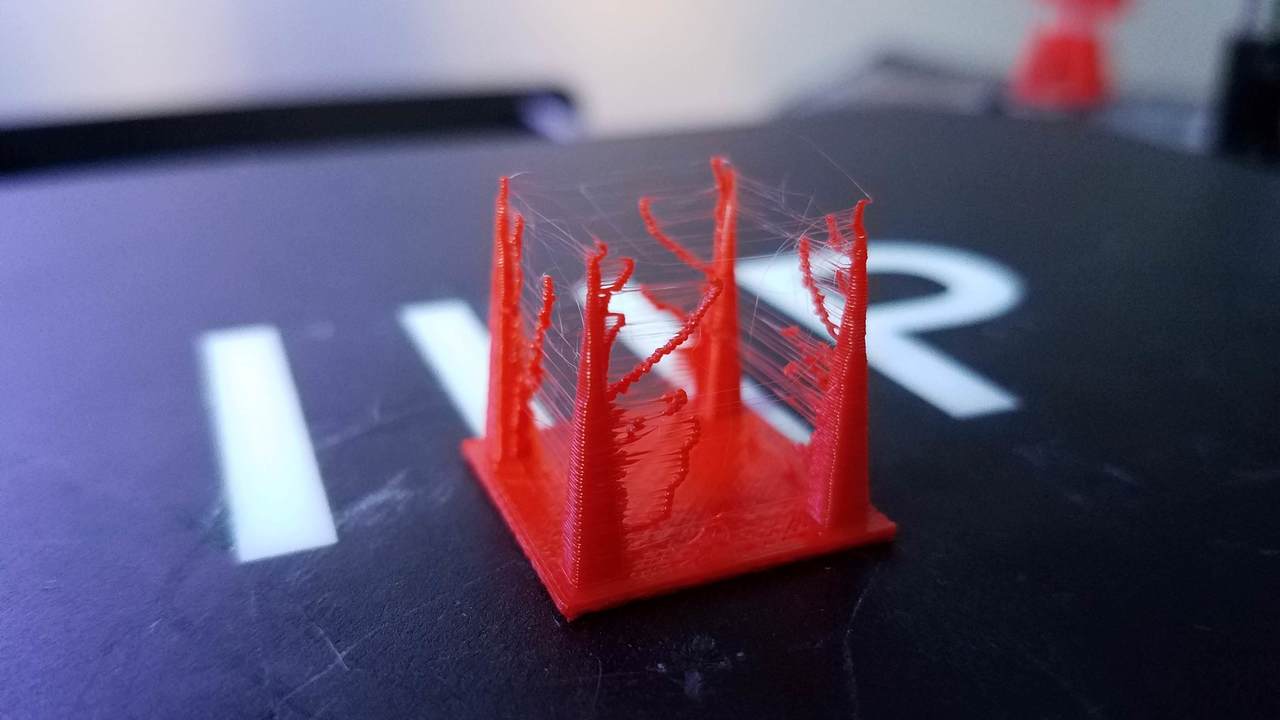

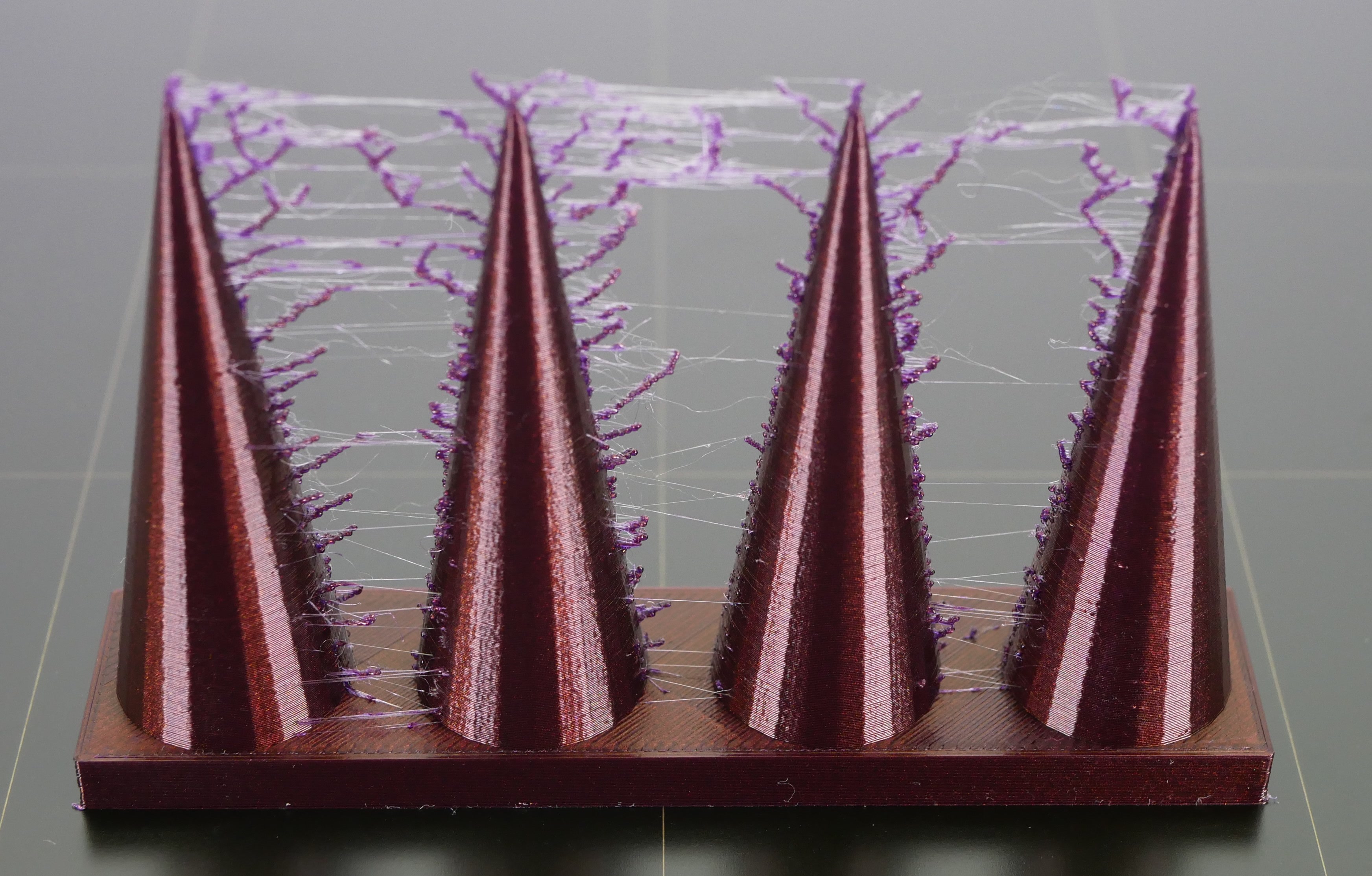

Causes of Stringing in 3D Printing Uncontrolled filament oozing between the 4 columns creates unwanted stringing. Stringing in 3D printing is primarily caused by the uncontrolled oozing of liquid filament during non-extrusion movements. This fundamental issue can arise from various factors and can be mitigated through several strategies.

How to put the string into 3D printers Easy3Dmaker YouTube

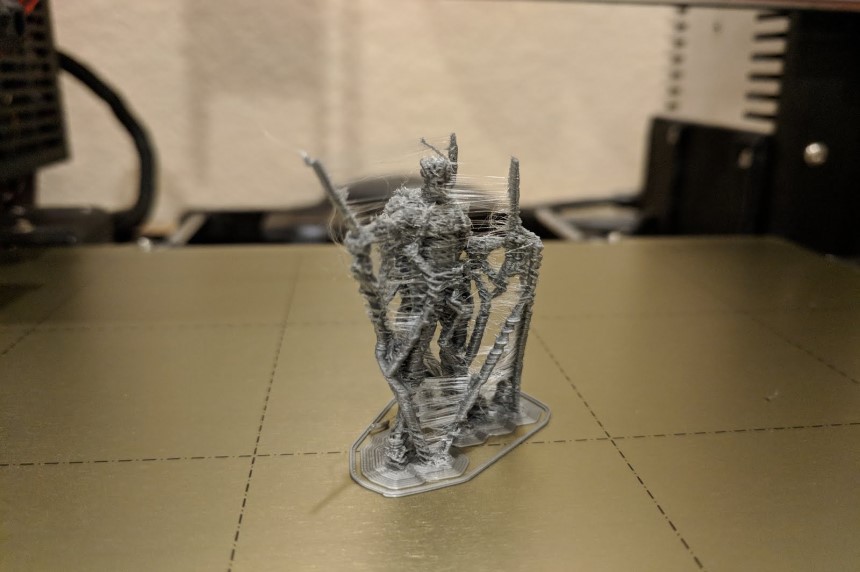

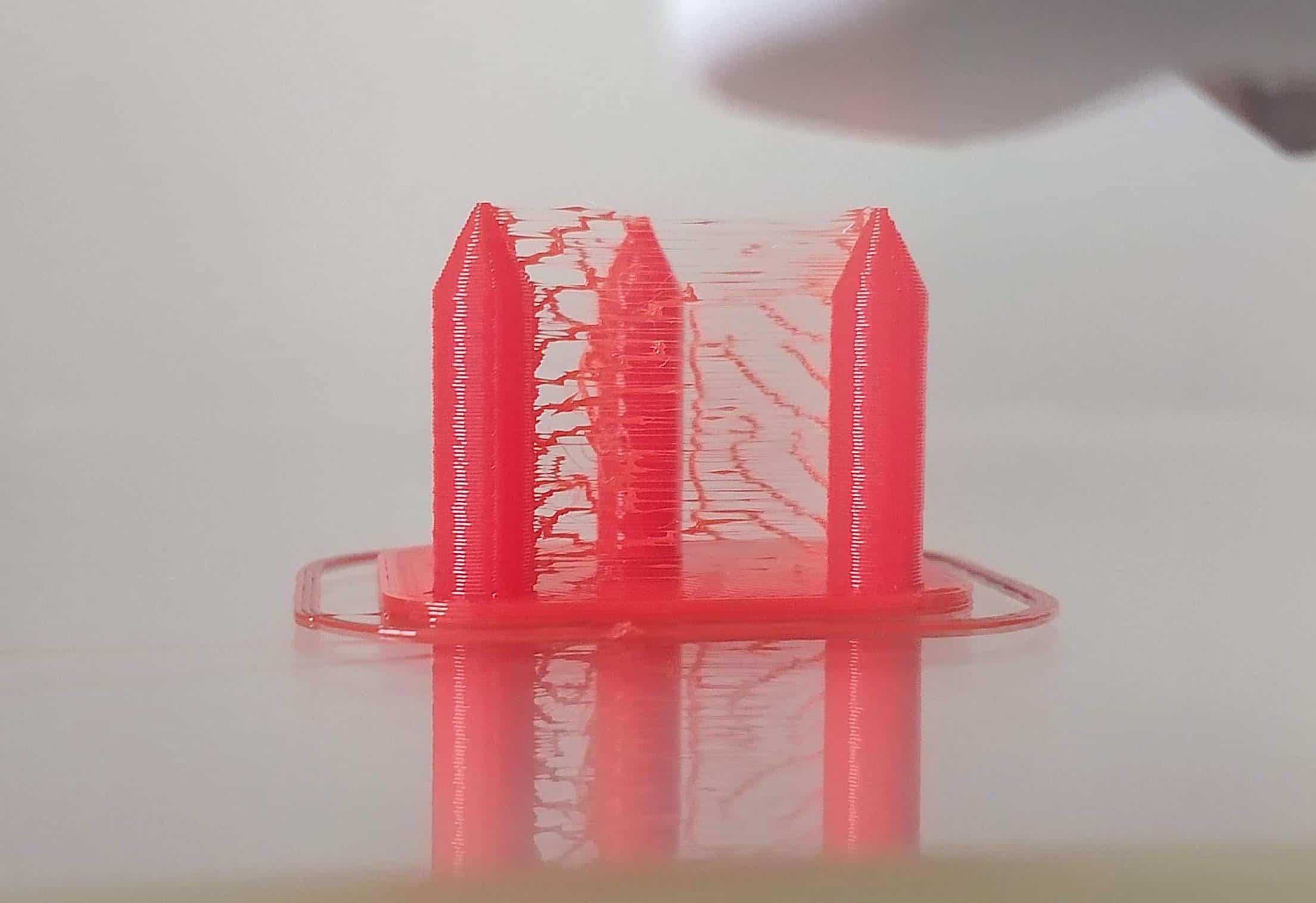

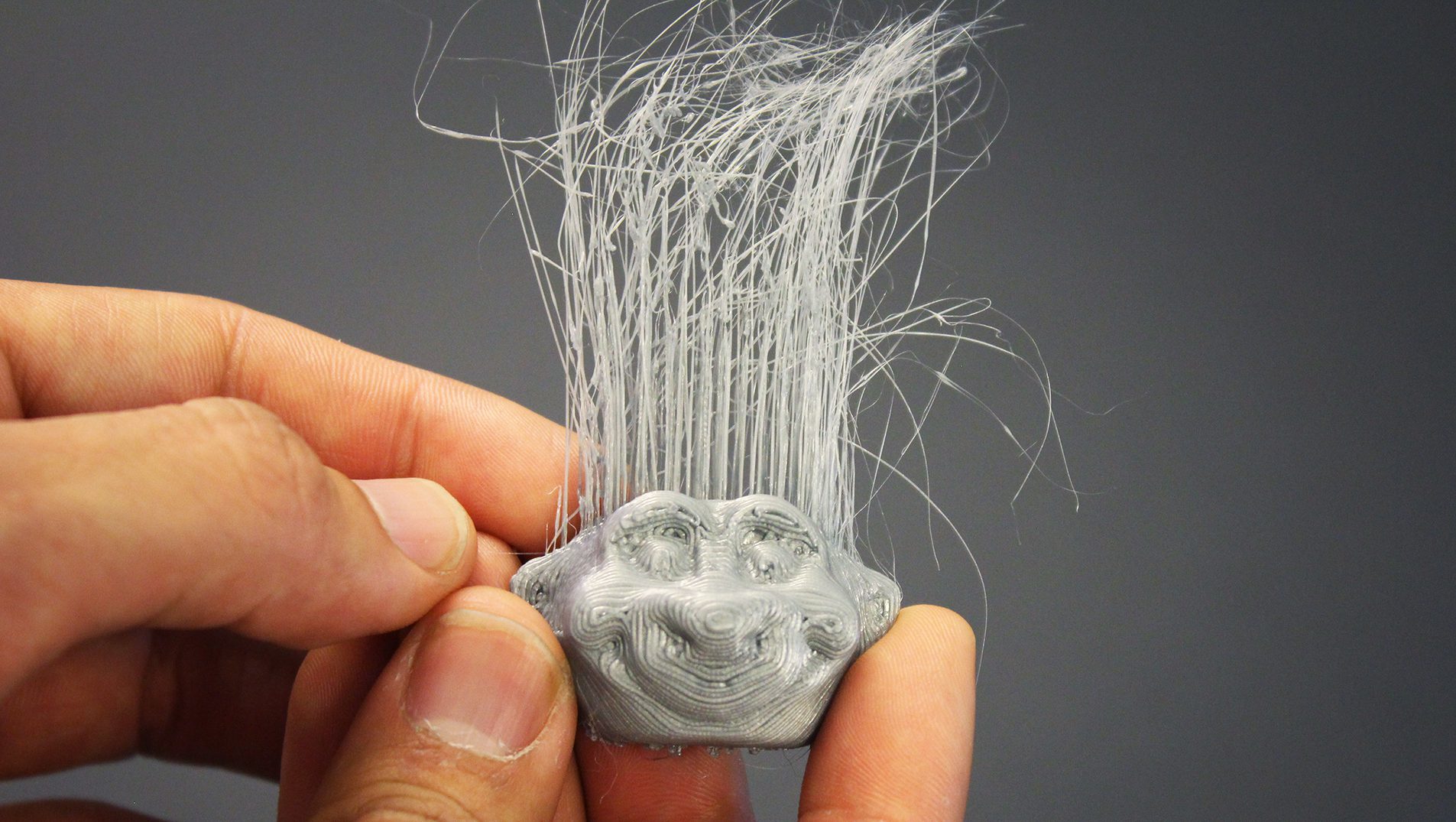

3D print stringing is a problem where the extruded filament accumulates on the design in thin strings, or "hairs", as the nozzle oozes filament when moving from one end to another. These strings can create a rough look on the surface of your 3D printed object.

Stringing in 3D Printing What Is It and How Do You Fix It? 3Dnatives Hiswai

What is 3D print stringing, you ask? It's those pesky little strings of plastic that sometimes appear between the parts of your print, marring its perfection. And why should you care? Well, it's simple: if you're as passionate about flawless prints as I am, understanding and preventing stringing is key to achieving those immaculate results.

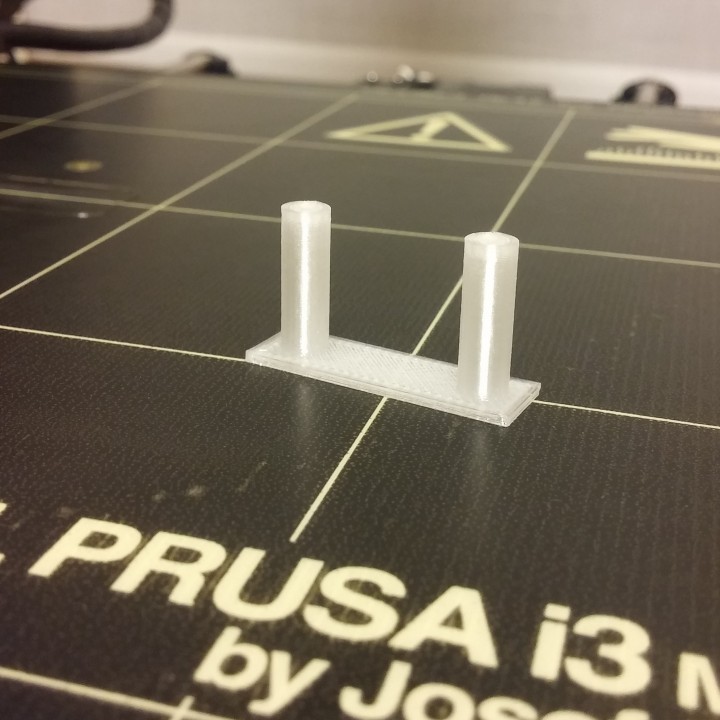

3D Printable Stringing test by Glen Waelbers

3D print stringing, also known as oozing or webbing, is a common issue that can mar the finish of your prints. It occurs when molten plastic leaks out of the nozzle and forms thin strands when the printer head moves from one point to another. Stringing can make 3D prints messy and unfinished, and weaken the structural integrity of the print.

TeamCambridgeJIC/3D Printing

Generally, 3D print stringing is the result of incorrectly set parameters. Not enough retraction or an excessive nozzle temperature can lead to stringing. Wet filament is another common culprit, especially for highly hygroscopic materials like PETG. Nozzle contamination, a defective nozzle, and poor filament quality are other possible causes.

3D Print Stringing What Is It and How to Prevent It

No Strings Attached 3D Printer Stringing: 5 Simple Solutions by Brian Obudho Updated Jan 12, 2024 3D printer stringing is a common problem, especially with flexible materials. Overcome this issue with these five simple solutions! 3D printer stringing is a common problem, especially with flexible materials.

3D Printer Stringing How To Fix It

1. Make sure your filaments are free from moisture All 3D printing filaments are prone to moisture pickup when exposed to open air. This moisture can be present in microscopic bubbles within the filament which can expand and burst when subjected to the temperatures of a hot end nozzle.

3D Printer Stringing 5 Simple Solutions All3DP

3D printing is an exciting technology that has revolutionized various industries, from manufacturing to healthcare. However, like any technology, it comes with its challenges. One common issue faced by 3D printing enthusiasts is "stringing." Stringing occurs when thin strands of filament are left behind between different parts of a printed object.

Troubleshooting Are your 3D Prints Stringing? Here’s What You Can Do! Geeetech Blog

How to Fix 3D Printer Stringy Layers (Best Method) October 25, 2023 3DSourced Rigid Ink, 3D Printing Guides, Guides Key Takeaways Enable retraction: Retraction pulls back the filament into the print head to prevent oozing. Check if it is activated and adjust the distance and speed.

3D Printer Stringing (6 Easy Fixes to Prevent It)

Stringing (otherwise known as oozing, whiskers, or "hairy" prints) occurs when small strings of plastic are left behind on a 3D printed model. This is typically due to plastic oozing out of the nozzle while the extruder is moving to a new location. Thankfully, there are several settings within Simplify3D that can help with this issue.

How To Fix Stringing On Your Prusa I3 Mk3s 3D Printer

3D print stringing is also known as oozing, and it occurs when small strings of plastic remain behind a 3D printed model. Plastic oozes out the nozzle when the extruder is moving to a new location. The good news is that stringing can be prevented with a couple of solutions. Retraction is the most popular setting used to curb the issue.

A Cura 3D Slicer Tutorial to Get Your Slicer Settings Right 3D Printer Power

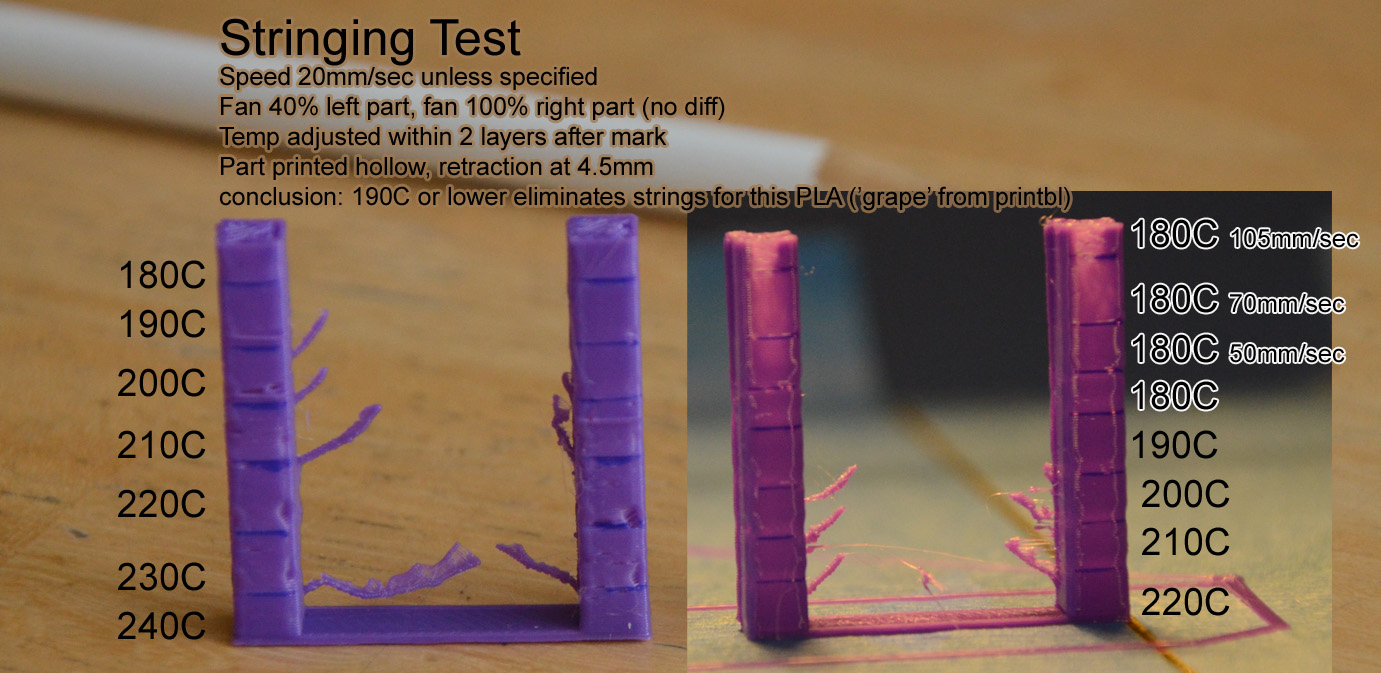

3D printing stringing can occur when the filament is too warm and starts to melt before it's supposed to, which causes it to droop and leave strings behind. In this case, you can try decreasing the temperature of the hot end (the part of the printer where the filament is heated and extruded) by a few degrees and see if that helps.

3d printer stringing test

The main causes of stringing are: incorrect retraction settings; excessive nozzle temperature; filament exposed to humidity; low print speed; external nozzle contamination; defective nozzle; large melt zone or a large diameter nozzle.

3D Printer Stringing (6 Easy Fixes to Prevent It)

1. Enable retraction The most reliable method to reduce stringing is to take advantage of your 3D printer's retraction feature. This should be enabled by default, but its settings can still be refined to get the best results. As its name implies, retraction pulls in a portion of the filament so that there is less pressure on the melt zone.

Troubleshooting Are your 3D Prints Stringing? Here’s What You Can Do! Geeetech Blog

Adjusting the default value every time in 5-10mm/s would be on the safe side to find the right retraction speed. 5 Solutions for preventing 3D Printer Stringing: 1. test the right retraction distance and retraction speed. 2. Lower the high printing temperature. 3. Reducing the print speed and increasing the travel speed. 4. Keep the nozzle clean.

3D Print Stringing What Is It and How to Prevent It

2. Increase Retraction Speed. Source: Youtube Make With Tech. The retraction speed is the second most relevant setting for fixing stringing. A 45 mm/s retraction print speed is the default for most slicer profiles, but if you're experiencing stringing, try going up to 50 mm/s.